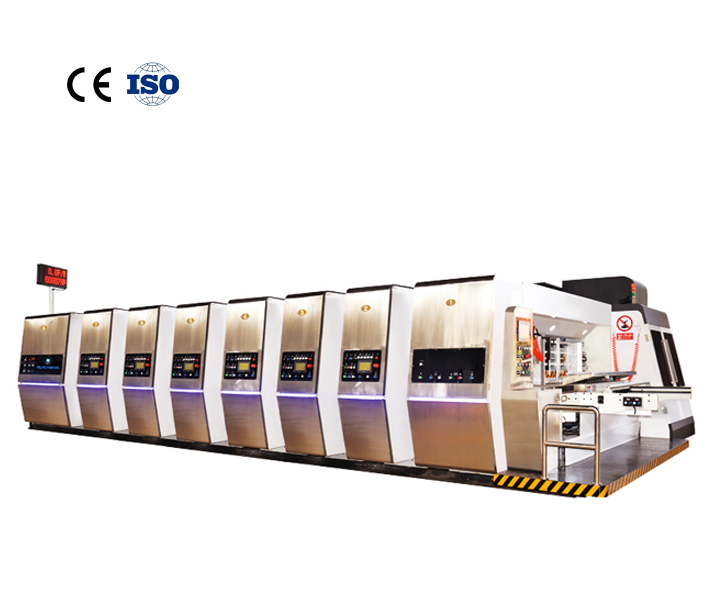

Taxanaha LJXCRG (Xayeysinta Hab-Dhaqameedka Buuxa, Mobile)

Astaamaha ugu muhiimsan

Mashiinka oo dhan waxaa loo qaabeeyey loona soo saaray iyadoo loo eegayo shuruudaha sare, isku halaynta iyo badbaadada.

· Dooro agab iyo qalab tayo sare leh. Dhammaan agabka rullaluistuyada wadista waxa ay ka samaysan yihiin bir tayo sare leh, chrome adag iyo dhulka.

Cutub kasta oo go'an wuxuu qaataa aaladda gudbinta xayaysiisyada vacuum adsorption, unugga daabacana wuxuu qaataa midabaynta kontoroolka servo si loo xaqiijiyo daabacaadda saxda ah ee saxda ah.

Mashiinka oo dhami wuxuu qaataa kontoroolka shaashadda taabashada ee PLC, kaas oo kaydin kara oo dib u soo celin kara xogta dalabka ee la abuuray. Beddelka amarada waa dhakhso iyo fududahay in la shaqeeyo.

· Helitaanka fog ee cilladaha shabakada si dhakhso ah loo tirtiro cilladaha qalabka.

Dib u dejin toos ah oo eber ah, dib u dejin toos ah.

• Ku hagaaji faraqa u dhexeeya rullaluistuyada qaada, rullaluistuyada dhejiska ah iyo rullaluhu anilox iyadoo la koontaroolayo kombayutarka.

Nidaamka ururinta dhexe ee boodhka warqadda.

Halbeegga tignoolajiyada

| Mashruuca/Nooca | RG920 | RG924 | RG1224 | RG1228 | |

| Xawaaraha ugu badan (qayb/daqiiqo) | 300 | 280 | 250 | 230 | |

| Saxnaanta quudinta warqadda (mm) | ±1.0 | ±1.0 | ±1.0 | ±1.0 | |

| Cabbirka quudinta ugu badan (mm) | 900x2100 | 900x2500 | 1200x2500 | 1200x2900 | |

| Cabbirka quudinta ugu yar (mm) | 300x600 | 300x600 | 350x600 | 350x600 | |

| Cabbirka warqadda sawiridda (mm) | 1200x2100 | 1200x2500 | 1500x2500 | 1500x2500 | |

| Aagga daabacaadda ugu badan (mm) | 900x2000 | 900x2400 | 1200x2400 | 1200x2800 | |

| Qalabka daabacaadda (mm) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | |

| Dhumucda saxanka caadiga ah (mm) | 7.2mm | 7.2mm | 7.2mm | 7.2mm | |

| Inta udhaxaysa boosaska ugu yar (mm) | Mindi wanaagsan | 130x130 | 130x130 | 130x130 | 130x130 |

|

| Scalpel | 230x65 | 230x65 | 230x65 | 230x65 |

| Qoto dheer ee ugu badan (mm) | 250 | 250 | 300 | 300 | |

| Saxnaanta xajinta (mm) | ±1.5 | ±1.5 | ±1.5 | ±1.5 | |

| Dhimashada saxnaanta goynta (mm) | ±1.0 | ±1.0 | ±1.0 | ±1.0 | |

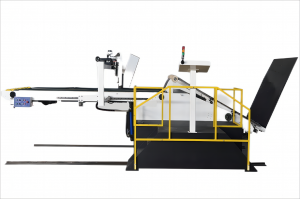

Qaybta quudinta warqadda

• Warqadda waxaa lagu quudin karaa si joogto ah ama si gooni gooni ah (oo leh miiska).

Ku quudi warqad leh rullaluistemadka cidhifka hore si aad u hagaajisid istaroogga quudinta warqadda oo aad u yarayso cadaadiska warqadda quudinta.

· Cidhifka hormoodka ahi waxa uu quudiyaa warqadda si uu u kordhiyo qulqulka nuugista, quudinta warqaduna waa mid deggan oo sax ah.

• Soo noqnoqoshada isbedbeddelka ahi waxay xakamaysaa qulqulka faakuumka iyo cadaadiska si loo waafajiyo cabbirka looxa.

· Roolaha caagga ah ee waraaqaha lagu quudiyo waa xabag laba-lakab ah, lakabka gudaha waa jilicsan yahay, lakabka sare waa adag yahay, kaas oo aan ilaalinaynin oo kaliya dabacsanaanta lakabka gudaha laakiin sidoo kale waxay hubisaa xirashada caabbinta dusha sare, hoos u dhigista fiditaanka iyo quudinta. ee kartoonnada.

Qalabka siigada: caday iyo marawaxad ka saar xaashida haraaga ah ee dusha kartoonada. Mareegayaal badan ayaa si toos ah loogu shubaa safaf badan oo buraash koronto ah iyo burush wareeg ah oo wareeg ah si loo kordhiyo boodhka dusha kartoonada.

· Jiid farqiga u dhexeeya rollerka waraaqaha, booska xaashida bidix iyo midig, hagaajinta kontoroolka kombiyuutarka.

Xawaaraha dejinta ka hor iyo ka dib kontoroolka korantada ee saxaarada danbe.

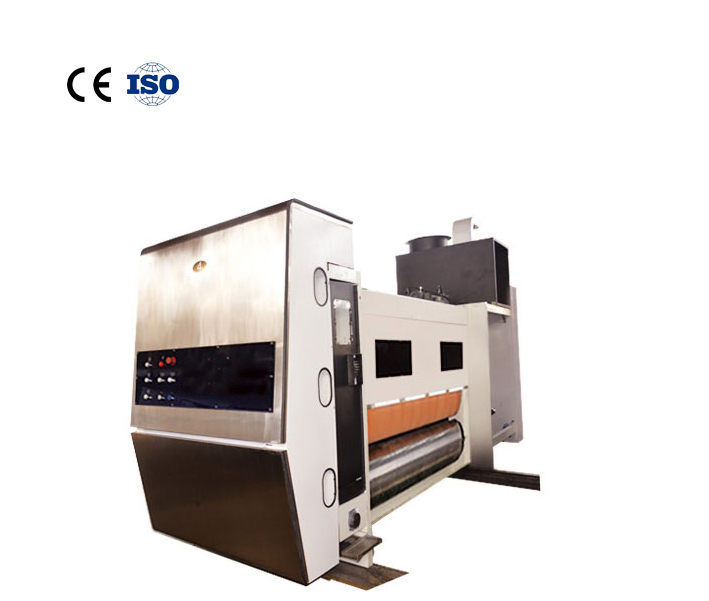

Qaybta daabacaadda

· Nooca Reel-laadista, 360 digrii qalab quful, taasoo ka dhigaysa nooca laadlaadsan si fudud oo sax ah.

Si dhakhso leh u beddel nooca oo si dhakhso leh u sax qaladka leexleexinta ee ka dhashay goobta si aad u gaadho xadka sixitaanka.

Gudbinta saxda ah ee saxda ah ee xayaysiinta vacuum inta lagu guda jiro habka oo dhan, saxnaanta sare ee daabacaadda.

Qaybta daabacaadda waa la ballaadhiyay si ay u caawiso qalinku engegan yahay oo loo hubiyo saxnaanta daabacaadda (nidaamka qalajinta ikhtiyaarka ah).

Marxaladda rullaluistemadka daabacaadda waxaa wada matoorka servo wuxuuna la jaan qaadayaa codeeyaha saxda ah ee Endat si loo hubiyo saxnaanta nidaamka wareegga servo. Nidaamka midabku wuxuu si toos ah ugu xiran yahay servo, kaas oo si degdeg ah u jawaabaya oo sarreeya.

Marxaladda horizontal, kontoroolka dhijitaalka ah ee kumbuyuutarka iyo korantada.

Nidaamka sahayda khad xoqida ee la soo dejiyey: qaybta ugu muhiimsan ee qolka khadku waa mid aan bir ahayn, maaddadu weligeed ma daxalisay, fududahay in la nadiifiyo; daabka si degdeg ah ayaa loo beddelaa.

Si toos ah u beddel qalabka nadiifinta si aad khad ka soo kabsato si tafatiran uga dhigto; khad iyo khad kaydi. Khadku wuxuu kaydin karaa khad mar kasta marka midab beddelo ama nadiifiyo 0.4 0.5 kg

Qalabka qamaarka

Qalabka rullaluistemadka ka horreeya: dalool koronto ku xidhidhiyaha, xariiqda riixitaanka iyo ka hor-cadaynta ayaa la dhammeeyaa hal mar.

Habaynta korantada ee dhererka, ballaca, dhererka iyo laalaabida kartoonka, bandhig dhijitaal ah.

• Gacanta ku hagaaji cadaadiska rullaluistemadka cadaadiska, garaacuna wuxuu muujinayaa qiimaha hagaajinta.

Dhumucdiisuna waxay tahay 7mm, walxo bir daawaha ah, daawaynta kulaylka qallafsan ee ilko shiidi, geeso fiiqan, saxsanaan sare.

Marxaladda boosaska leh waxaa lagu hagaajiyaa qiimaha korantada kombayutarka oo ah 360 digrii.

Ku dar salka caaryada godka gacanta.

• Qalabka xakamaynta silsiladda ayaa lagu rakibay qaybta go'an si loo gaaro joogsi degdeg ah, u joogsado ama dib u bilaabo quudinta waraaqaha.

Dhimista cutubka goynta

Matoorka Servo wuxuu xaqiijiyaa gariir yar ee qaybta daabacaadda iyo daabacaad sax ah.

• Magdhowga rullaluistemadka suufka waxaa wada matoor madaxbannaan si loo xakameeyo xawaaraha rullaluistuyada. Qiyaasta magdhowgu waa ± 3.5mm, kaas oo ilaalinaya rullaluistemadka suufka iyo xawaaraha duudduuban ee dhinta.

Qalabka dabaasha ee 50mm roller-ka caagga ah ayaa hagaajinaya nolosha suufka caagga ah.

Marxaladda horizontal, kumbuyuutarka iyo kantaroolka dhijitaalka ah ee elektiroonigga ah oo leh kala duwanaansho kontorool ah ± 10mm.

• Isku-habaynta wajiga dhimista waxaa wada PLC servo.

• Roolaha suufka caagga ah wuxuu gooyaa qaab-dhismeedka fidsan si uu dusha sare ee caaggu u ahaado mid siman.